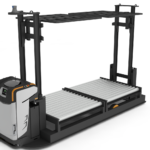

Conveyor AWT

The Rocla conveyor AGV is excellent for expanding the functionality of conveyor systems. It operates as an unfixed conveyor that is able to serve several fixed conveyors.

Key Benefits of Conveyor AWT

- Excellent for expanding the functionality of conveyor systems

- Operates as an unfixed conveyor

- Can serve several fixed conveyors

- Keeps operating area open for both human and forklift traffic

- Loads of up to 2 x 2,500 kg

- Transfer height of up to 950 mm

- Variable transfer height as an option

The Conveyor AWT is optimal for conveyor pick-up/drop-off

AGVs can be used in conveyor pick-ups and drop-offs, also known as handshakes. Mitsubishi Logisnext Europe offers a range of solutions for this storage option.

Conveyor AWT: fail-proof operations that keep material flowing

The Conveyor AWT which keep materials flowing. It serves as an unfixed conveyor that can pick up and deliver several conveyors. This keeps areas open for forklift and human traffic. Another factor is that conveyor system failure suspends all movement of material in the process. With the AGV system, the material keeps moving even if one vehicle is non-operational. The AGV system also leaves the floor space open for easy cleaning and maintenance.

The benefits of the Conveyor AWT are that it is Unfixed, allowing flexible application where needed. It is a conveyor extension, expanding the operations of existing conveyors. Unlike human operations, the Conveyor AWT is fail-safe, providing peace of mind. The Conveyor AWT is flexible, with variable transfer height available as an option. When used as an unfixed conveyor which serves several conveyors, it continues to allow the crossing of human and forklift traffic. Finally, the Conveyor AWT allows Vertical conveyor functionality as an option.

With all of these features, we are sure your logistics or manufacturing facility could benefit from automated guided vehicles and the Conveyor AWT as it seeks to make material flow safer and more reliable.

In the solution, the AGV is just the beginning of the story

Dimensional drawing 1

AWTxx Double Roller Conveyor ISO 1200×1000

Download this document to learn more about the dimensional and space requirements of the Conveyor AGV.

*Dimensions are indicative only. Details are subject to change.

Dimensional drawing 2

AWTxx Double Chain Conveyor ISO 1200×1000

Download this document to learn more about the dimensional and space requirements of the Conveyor AGV.

*Dimensions are indicative only. Details are subject to change.

Request a quote or more information

Would you like to start saving costs at your paper facility? Please send us a message and we will get back to you.

Lead Form

"*" indicates required fields